Worldwide 3D Laboratory Network for Process Mineralogy Services

Solving Mining Industry Problems

for over 20 years.

100+

pieces of equipment sold worldwide.

200+

reports for mining companies.

300+

research papers.

Hurdles that the 3D Laboratory directly addresses

Conventional sample preparation techniques are often not clean, leading to sample contamination. The 3D laboratory ensures contamination-free mineral processing.

Manual processes can result in low productivity, poor quality reports, and extended project timelines.

There's a notable absence of unified international standards for R&D reports in process mineralogy. The LIMS 3D-Technology Software component aims to provide unified reports.

Cross-border shipping of samples presents delays and complications. The 3D Laboratory network aims to allow samples to be processed in National 3D-Laboratories without requiring customs clearance at borders for over 10 countries.

Solutions

- Hydroseparation CNT HS-11

- Electric Pulse Disaggregation

- Mineural Module

WORLD’S FIRST COMPUTER CONTROLLED LABORATORY SCALE HYDROSEPARATOR OF PARTICLES BY PHYSICAL DENSITY

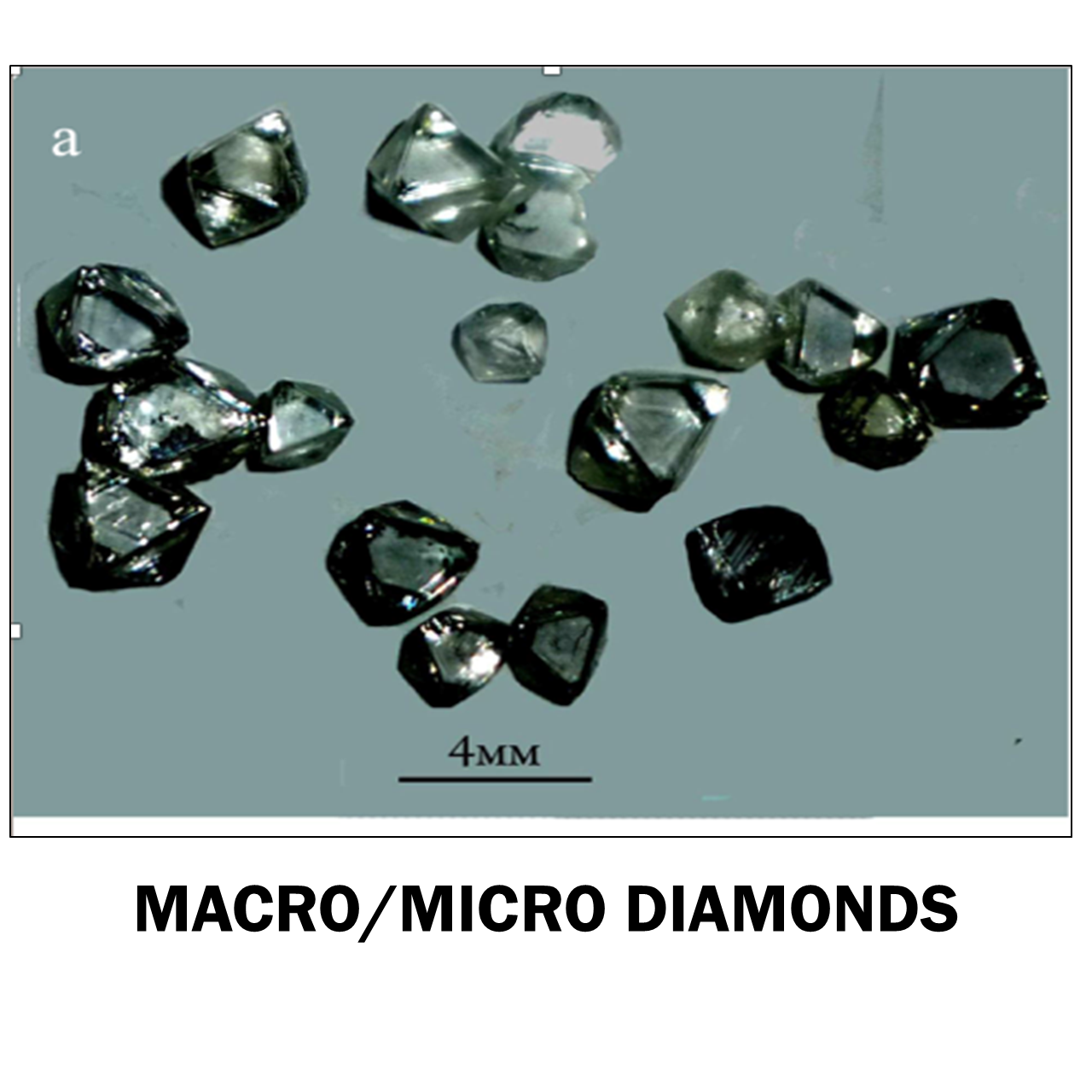

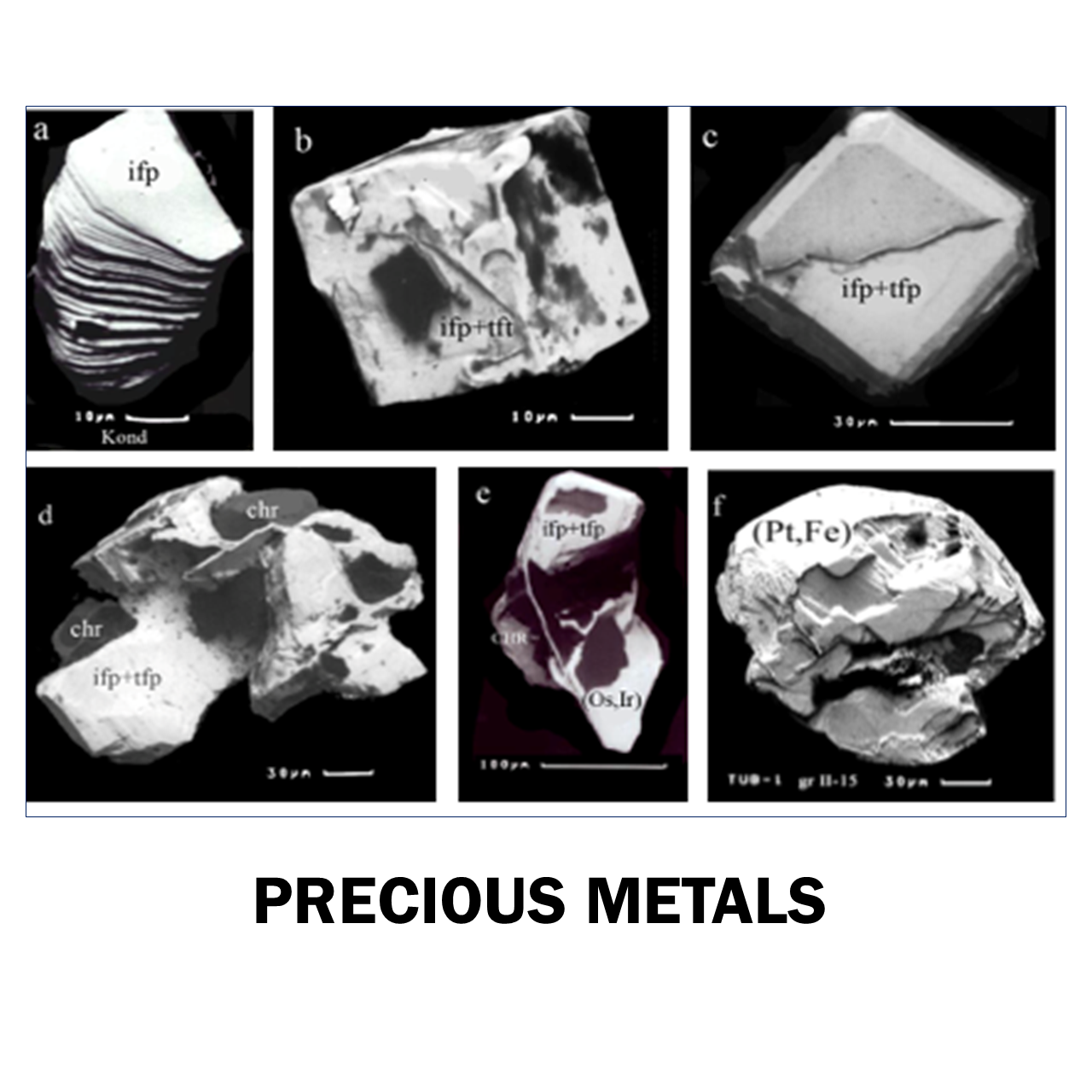

Hydroseparation (HS) is used to produce heavy mineral HS concentrates of grains from powdered samples that follow Stokes Law when settling in an upward-flowing pulsating water stream. Hydroseparators consist of two separate parts: a computer controlled water flow regulator (WFR) to modulate the water flow, pulse intensity and pulse rate, and a glass separation tube (GST). Sample material is introduced at the top of the GST. Light minerals move upwards in the GST, eventually flowing over the top into a collecting container outside the GST. Heavy minerals collect inside the GST at its base and are washed out after separation is completed. Ideally, mineral grains processed in a HS should have densities from 3–20 g/cm3 and be <0.3 mm. HS is optimal for recovery of very fine grained precious metal minerals from small (10s to 100s of g) samples that can’t be treated successfully by any other methods.

EPD SPARK-2 / SPARK-10

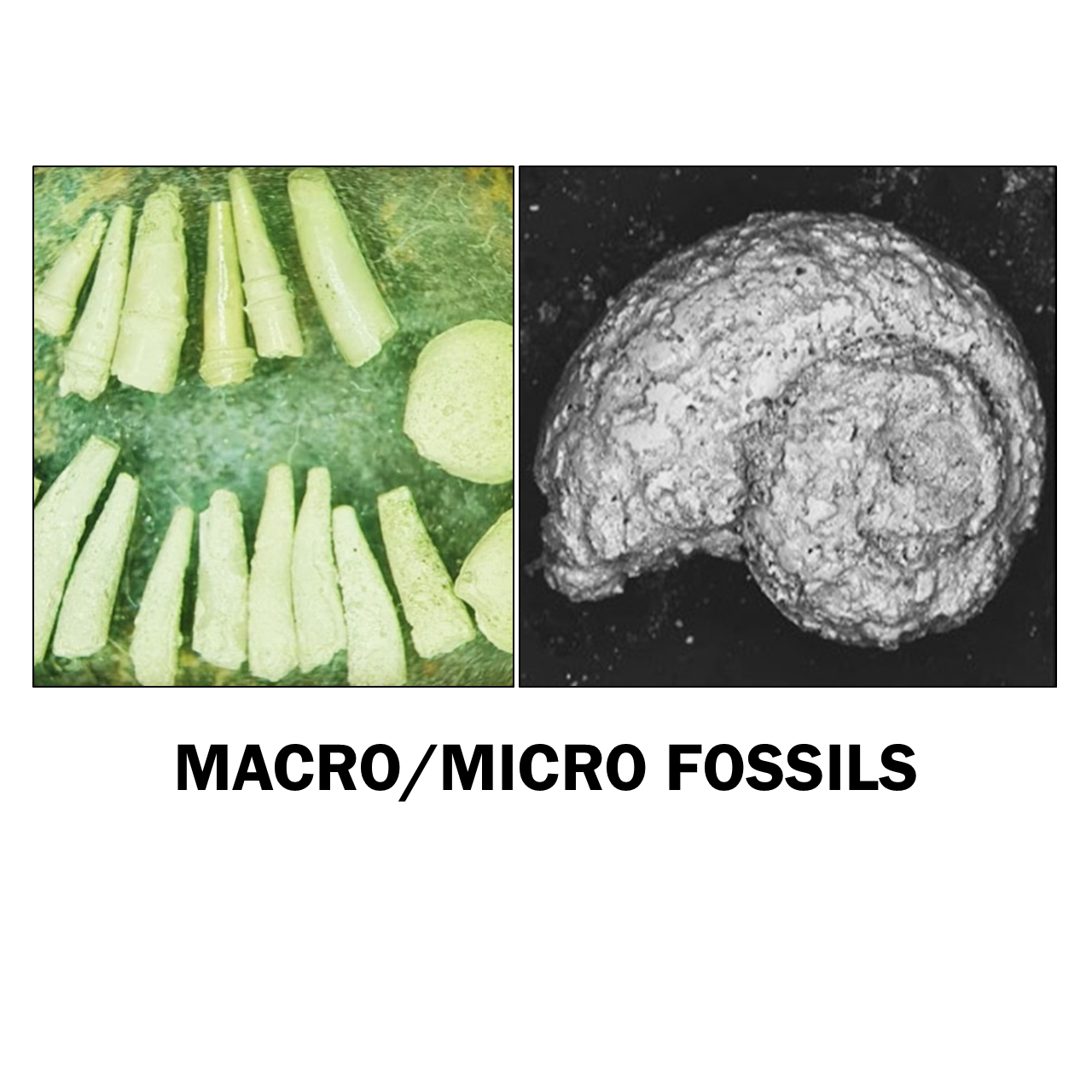

Electric pulse disaggregation (EPD) provides a fast and efficient means of liberating mineral grains from a rock irrespective of lithology or grain size along grain boundaries (zones of weakness). As a result, individual, undamaged mineral grains get recovered in their original shape. It is essential for mineralogical research and geochronology that EPD does not pose any risk of cross-contamination, does not break rock fragments or mark/damage grains as they are liberated; samples can be disaggregated right inside clean plastic bags which completely eliminates any sample handling mistakes.This also saves processing time since with conventional rock crushers, barren quartz should be disaggregated or crushed as a blank between samples to reduce and monitor contamination. EPD processing plants are also used for recovery of pristine crystals of diamond and gemstones from productive ores.

World’s first Neural Network for Mineral Identification & Characterization

- Comprehensive data from geological samples Characterization of mineral species

- Prediction of mineral composition of processed geological samples

- Determination of physical and chemical properties of mineral species (chemical composition, morphology, particle size, recovery, magnetic properties, density and others)

Products

CNT HS-11

WORLD’S FIRST COMPUTER CONTROLLED LABORATORY SCALE HYDROSEPARATOR OF PARTICLES BY PHYSICAL DENSITY

EPD SPARK-2

WORLD’S MOST POWERFUL

COMMERCIAL ELECTRIC PULSE DISAGGREGATOR

EPD SPARK-10

WORLD’S SMALLEST LABORATORY SCALE ELECTRIC PULSE DISAGGREGATOR

MinEye

COMPUTER VISION AND IMAGE ANALYSIS SYSTEM

MINEURAL

FIRST UX/UI FOR AUTOMATION OF MINERAL ANALYSIS BY NEURAL NETWORK

LIMS SOFTWARE

AUTOMATION IN PROCESS MINERALOGY

Where Precision Meets Profitability

Applications

- Minerals and oil exploration

- Tailings management

- Geometallurgy

- Mine planning

- Mineral processing

- Feasibility study

Contact us

Learn

- Internship programmes

- Career opportunities